Planning & Permits

Source: familyhandyman.com

How to add water pipe to backyard – Adding a water pipe to your backyard might seem straightforward, but proper planning and obtaining the necessary permits are crucial to avoid costly mistakes and potential legal issues. This section Artikels the steps involved in planning your project and securing the required approvals.Before you even think about digging, you need a solid plan. This involves determining the exact location of the new pipe, its length, diameter, and the type of pipe material you’ll use.

Consider factors like existing underground utilities (gas, electric, sewer lines), drainage patterns, and the location of trees and other landscaping features. Accurate measurements are essential for ordering the correct amount of pipe and fittings. You should also sketch a simple plan showing the pipe’s route, clearly marking its connection points to your existing water supply and any outdoor fixtures.

Permit Requirements

Securing the necessary permits is a non-negotiable step. Failing to do so can result in fines, project delays, and even the need to redo your work. The specific permits required will vary depending on your location and the scope of your project. It’s always best to err on the side of caution and contact your local authorities early in the planning process.

- Building Permit: Most jurisdictions require a building permit for any plumbing work, especially if it involves connecting to the main water line.

- Plumbing Permit: A separate plumbing permit might be needed, particularly if you’re not a licensed plumber and are hiring a contractor.

- Grading Permit: If your project involves significant excavation or earthmoving, a grading permit might be required to ensure proper soil management and erosion control.

- Right-of-Way Permit: If the pipe needs to cross any public property or easements, you’ll need a right-of-way permit.

Contacting Local Authorities

Contacting your local building department or permitting office is the first step in obtaining the necessary permits. Their website usually provides information on required permits, application forms, and fees. You can often find contact information, including phone numbers and email addresses, on the municipal website. When contacting them, be prepared to provide details about your project, including the location, proposed pipe route, and any relevant drawings or plans.

Be polite and clear in your communication, and ask any questions you may have about the application process.

Sample Permit Application Form

Permit application forms vary widely depending on location, but they typically include the following information:

| Field | Information |

|---|---|

| Applicant Name and Address | Your full name and residential address |

| Project Address | The location of the water pipe installation |

| Project Description | A detailed description of the work to be done, including pipe type, length, and location |

| Contractor Information (if applicable) | Name, license number, and contact information of the contractor |

| Site Plan | A simple sketch showing the location of the new pipe and its connection points |

| Permit Fee | The applicable fee for the permit |

| Applicant Signature and Date | Your signature and the date of application |

Remember to keep copies of all submitted documents and correspondence for your records.

Materials & Tools

Source: familyhandyman.com

Getting the right materials and tools is crucial for a successful backyard water pipe installation. Choosing the correct pipe type is key to longevity and avoiding leaks, while having the right tools makes the job easier and safer. This section details everything you’ll need.

Pipe Selection and Materials

Choosing the right pipe material depends on factors like your budget, soil conditions, and local regulations. Let’s look at some common options.

| Material | Quantity | Description | Purpose |

|---|---|---|---|

| PVC Pipe (Schedule 40) | Variable, depends on project length | Rigid, lightweight plastic pipe. Commonly used for water distribution. Comes in various diameters. | Main water line, branches. Cost-effective and easy to work with. |

| PEX Pipe | Variable, depends on project length | Flexible plastic pipe, often used with crimp fittings. Resistant to freezing. | Ideal for areas prone to freezing, easier to maneuver around obstacles. |

| Copper Pipe | Variable, depends on project length | Durable, long-lasting metal pipe. Resistant to corrosion. | High-quality, long-lasting option, but more expensive and difficult to work with than PVC or PEX. |

| PVC Fittings (Elbows, Tees, Couplings) | Variable, depends on project design | Connectors for changing pipe direction or joining sections. | Essential for creating the desired pipe layout. |

| PEX Fittings (Crimp Rings, Clamps) | Variable, depends on project design, used with PEX pipe only | Specialized fittings used to securely connect PEX pipe. | Used for creating watertight connections with PEX pipe. |

| Pipe Connectors (Unions, Adapters) | As needed, based on pipe types used | Allow for connecting different pipe types (e.g., PVC to PEX). | Useful for transitioning between different pipe materials. |

| Water Meter (if required) | 1 | Measures water usage. May be required by local regulations. | Accurate water usage tracking, potentially required by local codes. |

| Backflow Preventer (if required) | 1 | Prevents contaminated water from flowing back into the main water supply. Often required by local codes. | Ensures water safety and compliance with local regulations. |

| Pipe Insulation (optional) | As needed, depending on climate | Insulates pipes to prevent freezing in cold climates. | Protects pipes from freezing damage, extends pipe life. |

| Gravel (optional) | As needed, for pipe bedding | Provides support and drainage around the pipe. | Improves pipe stability and prevents waterlogging. |

Necessary Tools

Having the right tools is essential for a clean, efficient, and safe installation.

| Tool | Quantity | Description | Purpose |

|---|---|---|---|

| Pipe Cutter | 1 | Cuts PVC or copper pipe cleanly and accurately. | Creates precise cuts for clean pipe connections. |

| PEX Cutter (if using PEX pipe) | 1 | Cuts PEX pipe cleanly without damaging the pipe’s integrity. | Precise cuts for PEX pipe connections. |

| Pipe Wrench | 1 or 2 (different sizes helpful) | Tightens and loosens pipe fittings. | Secures pipe fittings, preventing leaks. |

| Crimping Tool (if using PEX pipe) | 1 | Crimps PEX fittings securely onto the pipe. | Creates secure and leak-proof connections for PEX pipe. |

| Level | 1 | Ensures the pipe is installed with the correct slope for proper drainage. | Prevents water pooling and ensures proper water flow. |

| Shovel | 1 | Digs trenches for burying the pipe. | Prepares the trench for pipe installation. |

| Measuring Tape | 1 | Measures pipe lengths and distances. | Ensures accurate pipe cutting and placement. |

| Safety Glasses | 1 | Protects eyes from debris and flying particles. | Essential safety equipment. |

| Work Gloves | 1 pair | Protects hands from cuts and abrasions. | Essential safety equipment. |

Excavation & Trenching

Source: familyhandyman.com

Digging the trench for your water pipe is a crucial step, and doing it right ensures a long-lasting and safe installation. This involves careful planning, the right tools, and a healthy respect for safety regulations. Remember, improperly dug trenches can lead to pipe damage, leaks, and even property damage.Proper trench excavation involves several key considerations, including depth, width, and safety precautions.

These factors are heavily influenced by local building codes and the specific soil conditions in your backyard.

Trench Depth and Width

The required depth and width of your trench will be dictated by local plumbing codes and the type of pipe you’re installing. Generally, the trench needs to be deep enough to protect the pipe from freezing temperatures and from damage from foot traffic or landscaping equipment. It also needs to be wide enough to allow for comfortable working space around the pipe during installation and any future maintenance or repairs.

For example, a typical residential water line might require a trench 24-36 inches deep and 12-18 inches wide, but always check your local codes for specific requirements. Compacted clay soils might require a wider trench than loose sandy soil to prevent cave-ins.

Safety Precautions During Excavation

Before you even touch a shovel, calling 811 (or your local equivalent) to have underground utilities marked is absolutely critical. This free service helps prevent accidental damage to gas lines, electric cables, or sewer lines, which can be dangerous and expensive to repair. Once the lines are marked, maintain a safe distance from them during excavation. Wear appropriate safety gear, including gloves, sturdy boots, and safety glasses.

If the trench is deeper than four feet, you should consider using shoring or trench boxes to prevent cave-ins, especially in unstable soil conditions. Always have someone nearby to assist, particularly if working in a deep trench.

Excavation Tools and Techniques

Several tools can be used for trenching, depending on the size of the job and the soil type. For smaller projects, a standard shovel is often sufficient. A post hole digger can be useful for digging straight, narrow trenches, while a trenching shovel is designed specifically for creating long, straight trenches. For larger jobs, a backhoe is a much more efficient option, especially in hard or rocky soil.

Remember to work in stages, removing soil carefully and frequently checking the trench depth and alignment. If you encounter rocks or other obstacles, use a pickaxe or other appropriate tools to carefully remove them. Avoid using excessive force, which can damage the pipe or surrounding utilities.

Pipe Installation & Connection

Source: revolutionarygardens.com

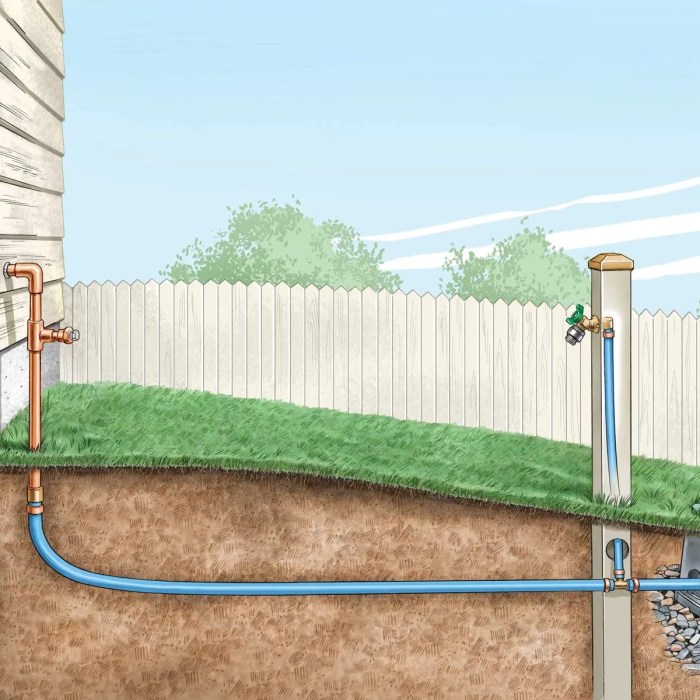

Now that the trench is dug and ready, it’s time to lay and connect your water pipes. This is a crucial step, as a poorly installed pipe can lead to leaks and costly repairs down the line. Take your time and follow these steps carefully.

Proper pipe installation involves carefully laying the pipe in the trench, ensuring a consistent grade, and securely connecting the sections using appropriate fittings. This section details the process, emphasizing leak prevention techniques.

Pipe Laying

Begin by laying the first pipe section at the starting point of your trench, ensuring it’s level and at the correct depth. Use a level to check the pipe’s alignment frequently. Imagine a long, straight line—that’s your goal. For long runs, consider using a laser level for greater accuracy. Gently lower the pipe into the trench, avoiding any sudden movements that might damage it.

Continue this process, section by section, connecting each piece as you go, always checking for level and alignment. Remember to maintain a consistent slope to allow for proper drainage. A slight downward slope towards your house or main water line is usually sufficient.

Pipe Joining and Fitting

Different pipe materials require different joining methods. For example, PVC pipes are typically joined using solvent cement and appropriate fittings such as couplings, elbows, and tees. Before applying the cement, ensure the pipe ends and fittings are clean, dry, and free from debris. Apply the cement evenly to both surfaces, following the manufacturer’s instructions. Push the pipe firmly into the fitting, rotating it slightly to ensure complete bonding.

Hold it in place for the recommended time, allowing the cement to set. For other materials like copper, you might use compression fittings or soldering, each with its specific techniques. Always refer to the manufacturer’s instructions for your specific pipe and fitting type.

Ensuring Leak-Free Connections

Leak prevention is paramount. Use the right type of sealant or adhesive for your pipe material. Apply a generous amount to all connections, ensuring complete coverage. Tighten fittings according to the manufacturer’s specifications. Over-tightening can damage the fitting and cause leaks.

After completing the installation, test for leaks by carefully filling the pipe with water. Check all connections closely for any signs of leakage. A slight dampness indicates a potential problem that needs to be addressed immediately before backfilling the trench. Imagine a drop of water clinging to a joint – that’s a warning sign. A steady stream requires immediate attention and likely a redo of the connection.

Visual Representation of Pipe Installation

Imagine a trench running from the street to your house. A PVC pipe, perhaps 1 inch in diameter, is placed in the bottom of the trench. It’s slightly angled downwards. Then, another section of pipe is carefully joined to the first using a PVC coupling. A small amount of solvent cement is visible at the joint.

This process continues along the trench, with occasional elbows and tees to change the direction or create branches. Each joint is carefully sealed and checked for leaks. The final section connects to the existing water line at your house. The whole pipe system resembles a gently sloping line, meticulously laid and securely connected.

Backfilling & Restoration: How To Add Water Pipe To Backyard

Source: familyhandyman.com

Carefully backfilling the trench and restoring your landscaping is crucial for a successful water pipe installation. Done incorrectly, settling could damage your new pipe and create future problems. This section details the best practices to ensure a long-lasting and aesthetically pleasing result.Backfilling the trench involves gradually replacing the excavated soil, ensuring the pipe remains undisturbed and protected. Proper compaction is vital to prevent future settling which can cause leaks and pipe damage.

Restoring the landscaping to its original condition is the final step in ensuring a seamless integration of the new pipe into your backyard.

Soil Backfilling Techniques, How to add water pipe to backyard

Backfilling should be done in layers, starting with finer soil near the pipe. This helps to avoid large rocks or debris that could damage the pipe. Each layer should be carefully compacted using a hand tamper or a small plate compactor. Avoid using heavy machinery directly above the pipe as this could cause crushing or shifting. The compaction process should continue until the backfill reaches the original ground level.

Using a slightly damp soil can help achieve better compaction. For example, a 6-inch layer of soil near the pipe would be compacted before adding another 6-inch layer. This layered approach, coupled with proper compaction, minimizes the risk of settling and pipe damage.

Compaction Importance and Methods

Compacting the soil around the pipe is paramount to prevent settling. Settling can put stress on the pipe joints, leading to leaks and potential failure. Using a hand tamper for smaller trenches allows for precise compaction around the pipe. For larger trenches, a small plate compactor can be rented, offering more efficient compaction. The goal is to achieve a soil density similar to the surrounding undisturbed soil.

Improper compaction can lead to voids around the pipe, which can cause the pipe to shift or settle unevenly over time. For instance, a poorly compacted trench might settle several inches over a year, putting pressure on the pipe joints.

Landscaping Restoration

Restoring your landscaping involves replacing the topsoil and sod or planting new grass seed. Before replacing topsoil, ensure the ground is level. If necessary, use additional topsoil to fill any remaining gaps or low spots. For sod, carefully lay it down, ensuring complete contact with the soil. Water thoroughly after installation.

If using grass seed, follow the instructions on the seed packet, which usually involves raking the soil, scattering the seed, and covering it with a thin layer of topsoil. Regular watering is crucial for successful seed germination. Remember to avoid walking on the newly planted grass until it has established a strong root system. You might consider adding a layer of mulch to retain moisture and prevent weed growth.

This will help maintain the integrity of the restored area.

Testing & Inspection

Source: amazonaws.com

After all the hard work of digging, laying pipe, and backfilling, the final and crucial step is testing your new water line to ensure it’s leak-free and ready for years of service. This involves a pressure test to confirm the pipe’s integrity and identify any potential problems before they become major headaches. Neglecting this step could lead to costly repairs down the line, so it’s worth taking the time to do it right.Pressure testing verifies the pipe’s ability to withstand the pressure of your water system.

A successful test gives you peace of mind, knowing your investment is secure. Failure to properly test could result in hidden leaks that damage your landscaping or even your foundation over time.

Pressure Testing Procedure

The pressure test involves filling the pipe with water and then pressurizing it to a level exceeding the normal operating pressure of your water system. Typically, this is done using a pressure gauge and a water pump, but the exact procedure might vary slightly depending on local codes and the specific type of pipe used. Before starting, ensure all connections are tight and secure.

Slowly increase the pressure, monitoring the gauge closely for any pressure drops that might indicate a leak. Maintain the pressure for a specified period (usually a few hours) to allow any minor leaks to become apparent. If the pressure remains stable, the test is successful.

Documenting the Testing Process

Maintaining detailed records of the pressure test is vital. This documentation serves as proof of proper installation and can be crucial if any problems arise later. Your records should include the date and time of the test, the maximum pressure achieved, the duration of the pressure test, the initial pressure, any pressure drops observed, and a description of the location and nature of any leaks discovered.

Include photos of the pressure gauge readings at various points throughout the testing process. A signed statement confirming the successful completion of the pressure test by a qualified plumber (if one was used) should also be included in your documentation.

Troubleshooting Leaks and Pipe Failures

Even with careful installation, leaks can occur. Small leaks might be visible as damp spots on the ground. Larger leaks might manifest as significant water flow. If leaks are found during the pressure test, carefully examine the pipe sections where pressure drops occurred. Common causes of leaks include loose connections, damaged pipe sections, or improperly installed fittings.

Repairing leaks involves excavating the affected area, repairing or replacing the damaged section of pipe, and retesting the system. If the leaks are extensive or you are unsure how to repair them, contacting a licensed plumber is crucial. Attempting complex repairs without proper training can cause further damage and lead to costly mistakes. Remember, safety is paramount, so always turn off the water supply before making any repairs.

Water Meter & Connection

Source: exmark.com

Connecting your new backyard water line to your home’s existing water supply requires careful planning and execution. This process typically involves connecting to the main water line, often near the street, and includes the installation of a water meter to accurately track your water usage. This section details the steps involved and explains the importance of proper installation and connection.The water meter acts as a crucial component in your water system, measuring the volume of water passing through your line.

This information is used by your water utility company to accurately bill you for your consumption. Accurate metering ensures fair billing and helps in detecting potential leaks or unusually high water usage.

Water Meter Installation

Installing a water meter, if necessary, requires precision and adherence to local plumbing codes. It’s usually best left to a licensed plumber, especially if you are unfamiliar with plumbing systems. However, understanding the general process can be helpful. The process generally involves carefully cutting into the existing water line, inserting the meter, and securely connecting the pipes on either side.

This requires specialized tools and knowledge of pressure ratings to ensure a leak-free connection. Properly sealing all connections is vital to prevent water leaks and maintain water pressure. Failure to do so could result in significant water damage and wasted water.

Water Meter Types and Connections

Several types of water meters exist, each with its own connection method. Common types include disc meters, turbine meters, and compound meters. Disc meters are widely used for residential applications due to their simplicity and accuracy in measuring low to medium flow rates. Turbine meters are suitable for higher flow rates, often seen in commercial settings. Compound meters combine the features of disc and turbine meters, offering accurate measurements across a wider range of flow rates.

The specific connection type will depend on the meter and your existing pipe size and material. Common connection methods include threaded connections, flanged connections, and compression fittings. It’s crucial to select a meter and connection method compatible with your existing water line and local plumbing codes. For instance, a meter with threaded connections would require threaded pipe ends, and a flanged connection would require flanges on both the meter and the pipe.

Incorrect connections can lead to leaks and meter malfunction.

Connecting to the Main Water Line

Connecting the new water pipe to the main water line is a critical step and should be performed by a qualified plumber. This often involves excavating to access the main water line, usually located near the property line. Once access is gained, the main line is shut off to allow for safe connection. The connection is typically made using appropriate fittings that match the pipe material and diameter of both the main line and the new water line.

The connection must be secure and watertight to prevent leaks and maintain consistent water pressure throughout the system. After the connection is complete, the main water line is carefully reopened and the system is tested for leaks. Local regulations may require permits and inspections for this work. Ignoring these regulations can result in fines or legal issues.

Ultimate Conclusion

Adding a water pipe to your backyard can significantly enhance its functionality and beauty. By following the steps Artikeld in this guide, you’ve equipped yourself with the knowledge to tackle this project confidently and safely. Remember to always prioritize safety and double-check your work at each stage. With a little patience and attention to detail, you’ll soon be enjoying the benefits of a new water source in your outdoor oasis.

Happy gardening (or whatever your backyard project may be!)